Historically, potato crates have always been tracked by hand.

Each crate had its own label, usually stapled to the palox, to identify its contents. A board or squared sheets, often placed at the entrance to storage, were used to manage the daily status of potato stocks.

However, the evolution of potato production operations, the growing number of crates to be managed, customer requirements in terms of traceability, the need for farm profitability and the arrival of new technologies have led to the emergence of new solutions.

And so, in 2018, the SAALTO company was created. SAALTO stands for Système Autonome et Automatique de Localisation et Traçabilité d’Objets.

Accompanied by a number of potato growers, the SAALTO team set out to find simple, effective solutions to digitize the business of storing potatoes in paloxes.

The first SAALTO solution was launched in 2019 with a restricted circle of potato growers, mainly seed and ware potato growers, to test the prototypes and validate the general concept.

On the strength of these initial successful tests, SAALTO took flight and set out to conquer French potato growers. Today, SAALTO is the French leader in potato storage management solutions, and is present on many French farms.

How does the SAALTO system work?

The SAALTO system comprises a hardware component and an online platform.

The hardware is based on the unique, patented IdMatic technology:

- RFID tags:

Each checkout has its own RFID tag. The tag is triple-identified, enabling data to be read and archived in total security. These tags are resistant to dust and sunlight, and come with a 20-year warranty!

- A SAALTO reader:

A unique, fully built-in SAALTO reader fits between the forks of forklift trucks. The SAALTO reader is a concentrate of technology. It is made up of numerous sensors, linked together by powerful algorithms. The result is automatic and immediate reading of potato boxes.

- A SAALTO cabin tablet :

Each forklift operator has his own SAALTO tablet in the cab of his forklift. This digital interface enables forklift drivers to know exactly which boxes are in front of them, to check the condition of the refrigerators, to validate certain operations and to receive new assignments to carry out.

IdMatic technology enables forklift drivers to concentrate on their core activity – handling pallets – without having to worry about entering information into the SAALTO solution. It’s all automatic!

As a result, forklift drivers are empowered and more autonomous, with more efficient planning of their tasks.

La plateforme en ligne

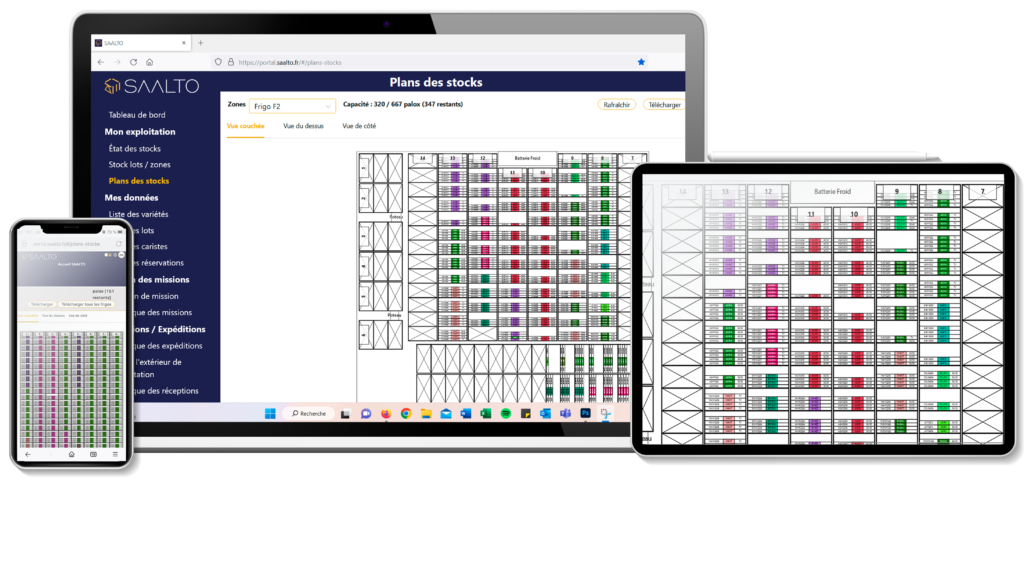

SAALTO’s online potato storage management platform is accessible on all digital media (PC, tablet and smartphone), anywhere in the world, 24/7.

Today’s potato grower has to react quickly to customer demand. The same applies to storage, which has to react quickly to different fluctuations. That’s why the SAALTO system makes it possible to manage large volumes of crates and carry out precise operations using digitized, personalized refrigerated storage processes. The forklift operator instantly receives all new assignments on his SAALTO tablet, for improved responsiveness.

SAALTO software helps potato growers to manage and control daily operations in storage warehouses, from the arrival of potatoes to their removal. It offers real-time visibility of all fridges, even if they are in different geographical locations.

In addition to inventory management, the SAALTO system offers tools for order preparation and packaging processes, data processing, mission analysis, etc.

The SAALTO online platform is a powerful tool for optimizing the management of potato storage fridges, and monitoring order reception, stock management, preparation, packaging and dispatch processes. Everything is organized from a single, ergonomic interface. This interface also enables data and resources to be used, as well as multi-criteria mission analysis. The SAALTO management system can be integrated with other tools, such as ERP or handheld technological objects.

The advantages of a digital potato storage management system :

A high-performance, digital storage management system is essential for all growers who have to manage potato stocks, as it saves money while improving efficiency and productivity in many areas. Below you’ll find the main benefits of the SAALTO system:

- Time-saving storage management

- Add value to your entire potato production

- Secure your traceability

- Improve your carbon footprint

- Empowering your forklift drivers and building loyalty

- Simplify your storage organization

- Improve customer relations

The SAALTO system is a real digital tool for potato and onion growers!

Get more information by downloading the attached brochure!

Do you have a question? Do you have a need? CONTACT US!